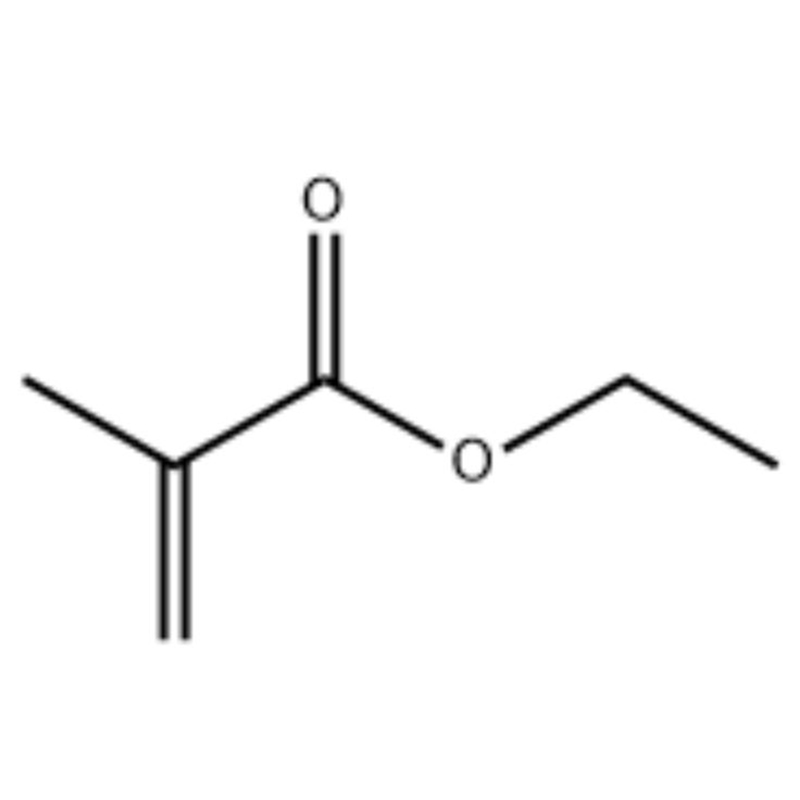

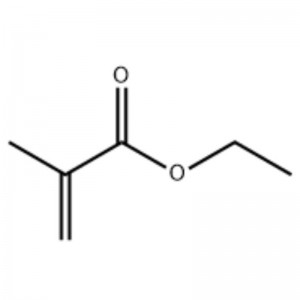

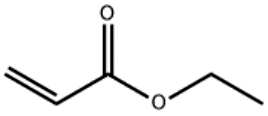

Ethyl methacrylate

| Khoom npe | Ethyl methacrylate |

| Synonyms | Methacrylic acid-ethyl ester, ethyl2-methacrylate |

| 2-METHYL-ACRYLIC ACID ETHYL ESTER, RARECHEM AL BI 0124 | |

| MFCD00009161, Ethylmethacrylat, 2-Propenoic acid, 2-methyl-, ethyl ester | |

| Ethyl 2-methyl-2-propenoate, Ethyl methacrylate, ethyl 2-methylpropenoate | |

| Ethylmethylacryate, 2OVY1 & U1, Ethyl methylacrylate, Ethylmethacrylate, EMA | |

| EINECS 202-597-5, Rhoplex ac-33, Ethyl-2-methylprop-2-enoat | |

| 2-PROPENOIC ACID, 2-METHYL-, ETHYL ESTER | |

| CAS nr | 97-63-2 : kuv |

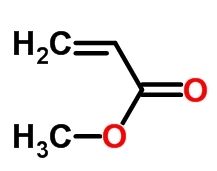

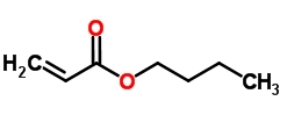

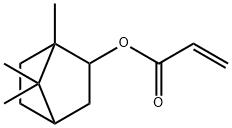

| Cov mis mos molecular | C6H10O2 |

| Molecular hnyav | 114.14 Nws |

| Cov qauv qauv | |

| EINECS tus lej | 202-597-5 |

| MDL Nr. | PAB 00009161 |

Melting point -75 ° C

Kub taw tes 118-119 ° C (lit.)

Qhov ceev 0.917 g / mL ntawm 25 ° C (lit.)

Vapor ceev> 3.9 (vs huab cua)

Vapor siab 15 mm Hg (20 ° C)

Refractive index n20/D 1.413 (lit.)

Flash point 60 ° F

Cia tej yam kev mob 2-8 ° C

Solubility 5.1g / l

Daim ntawv ua kua

Cov xim yog Clear colorless

Acrid Acrid tsw.

Flavour acrylate

explosive txwv 1.8% (V)

Solubility dej 4 g / L (20 ºC)

PAB 471201

Polymerizes nyob rau hauv lub xub ntiag ntawm lub teeb los yog kub. Incompatible nrog peroxides, oxidizing agents, bases, acids, txo tus neeg sawv cev, halogens thiab amines. Flamable.

PEB 1.940

Hazard Symbol (GHS)

GHS02, GHS07

Kev phom sij

Hazard Description H225-H315-H317-H319-H335

Kev ceev faj P210-P233-P240-P280-P303+P361+P353-P305+P351+P338

Dangerous Goods Mark F,Xi

Hazard qeb code 11-36/37/38-43

Cov lus qhia txog kev nyab xeeb 9-16-29-33

Dangerous Goods Transport Code UN 2277 3/PG 2

WGK Germany 1

RTECS No. OZ4550000

Kev kub ntxhov combustion kub 771 ° F

TSCAYes

Kev phom sij 3

Ntim Qeb II

Kev lis kev cai Code 29161490

LD50 qhov ncauj hauv luav: 14600 mg/kg LD50 dermal Luav > 9130 mg/kg

Khaws rau hauv qhov chaw txias, qhuav, qhov cua zoo, thiab khaws qhov kub hauv qab 30 ° C.

Ntim hauv 200Kg / nruas, lossis ntim raws li cov neeg siv khoom xav tau.

Feem ntau siv polymeric monomers. Nws tuaj yeem siv los ua qhov nruab nrab rau cov nplaum nplaum, txheej txheej, cov tshuaj kho fiber ntau, cov ntaub ntawv molding, thiab tseem siv rau kev tsim cov acrylate copolymer. Nws tuaj yeem ua tau copolymerized nrog methyl methacrylate los txhim kho nws cov brittleness, thiab tseem siv rau hauv kev tsim cov plexiglass, hluavtaws cob thiab molding hmoov. 2. Siv rau kev npaj cov polymers thiab copolymer, hluavtaws resins, plexiglass thiab coatings.